Hardware manufacturers in critical infrastructure sectors face mounting complexity in managing supply chains while adhering to strict regulatory requirements and internal policies. Companies building mission-critical products – from rocket ships and satellites to robotics and autonomous vehicles – need to source parts quickly and efficiently, often in smaller volumes than traditional manufacturing operations support. Cofactr addresses these challenges with its comprehensive supply chain and logistics management platform, streamlining everything from parts sourcing to supplier procurement and delivery tracking. The platform serves over 50 companies across high-compliance sectors like aerospace, defense, and medical technology, as well as consumer-facing industries such as autonomous vehicles and wearables. By creating a seamless link between Product Lifecycle Management, Enterprise Resource Planning, and Manufacturing Execution Systems, Cofactr enables organizations to maintain rigorous compliance while accelerating their product development cycles. The platform provides access to a network of pre-vetted suppliers and runs on AWS’s Government Cloud, meeting the stringent security requirements of regulated industries that must maintain domestic manufacturing capabilities.

AlleyWatch caught up with Cofactr Cofounder and CEO Matthew Haber to learn more about the business, the company’s strategic plans, latest round of funding, which brings the company’s total funding raised to $28.8M, and much, much more…

Who were your investors and how much did you raise?

We raised $17.2M for our Series A funding round. The raise was led by Bain Capital Ventures and was joined by existing Seed investors Y Combinator, Floating Point Ventures, Broom, and DNX.

Tell us about the product or service that Cofactr offers.

Cofactr is a supply chain and logistics management platform that streamlines supply chains for high-compliance organizations and agile hardware teams, making them accurate, efficient, and easy to manage. We work with companies that build everything from rocket ships, satellites and drones to robotics, autonomous vehicles and wearables. These companies not only need to produce and source fast while navigating stringent internal policies and financial controls, but those in regulated industries additionally need to do it domestically to comply with governmental requirements.

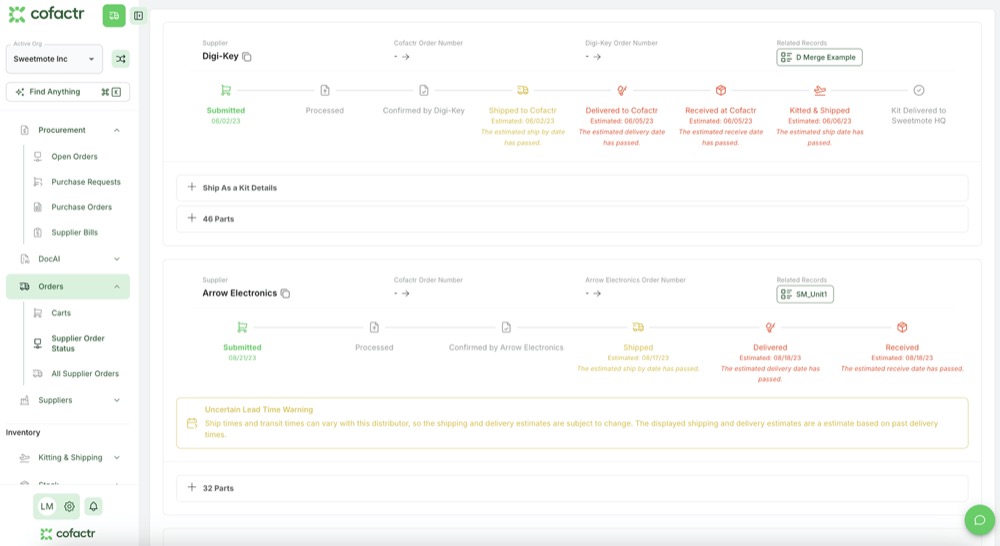

Our single unified platform automates and manage the complexities of these otherwise disparate operations and compliance processes, including parts sourcing, supplier procurement from a network of pre-vetted suppliers, approving and paying for orders, handling shipping and customs and tracking delivery progress and real-time stock availability.

To meet the requirements of high-compliance industries we work with, we’re compliant ourselves. Cofactr is ITAR and SOC 2 compliant and runs entirely on AWS’s Government Cloud.

What inspired the start of Cofactr?

My cofounder Phillip Gulley and I were working on the engineering and solutions side of hardware with our previous company, BeSide Digital. We experienced first-hand the challenges of building and scaling hardware and we saw it reflected in our clients as well–it felt extremely laborious compared to software and there were so many separate moving parts at all times. After we sold BeSide, we were driven to solve the problems of electronic supply chain and logistics by creating a company that could bridge this gap between bringing ideas to life and scaling them effectively.

My cofounder Phillip Gulley and I were working on the engineering and solutions side of hardware with our previous company, BeSide Digital. We experienced first-hand the challenges of building and scaling hardware and we saw it reflected in our clients as well–it felt extremely laborious compared to software and there were so many separate moving parts at all times. After we sold BeSide, we were driven to solve the problems of electronic supply chain and logistics by creating a company that could bridge this gap between bringing ideas to life and scaling them effectively.

Our journey to Cofactr wasn’t entirely linear, though. Our goal was always to build a company that we wish had existed when we were on the engineering side of things. We initially started as a contract manufacturer for circuit board assembly but then quickly realized that it wasn’t the right avenue to address the larger pain points we were seeing, such as the inefficiencies and lack of streamlined tools in the hardware supply chain. We then pivoted to building electronics-specific third-party logistics and procurement automation tools, which eventually evolved into the Cofactr of today.

How is Cofactr different?

We’re the only end-to-end electronics procurement and logistics solution. While other solutions are focused on the data and intelligence applications of supply chain, we’re focused on those plus the physical applications. Using Cofactr, companies can manage parts sourcing and handle supplier procurement–and also move items between vendors, ship and track delivery progress, secure warehouse locations, understand real-time stock availability and more. Rather than focusing on isolated aspects of the supply chain like many solutions do, we handle it all–in one place.

We’re also the only company designed to streamline supply chain for high-compliance organizations and agile hardware teams. We deeply understand the nuances of the companies in industries like aerospace, defense, robotics, automotive and medical technology. Most of these companies are typically reliant on generic procurement and supply chain software that is not built for the speed and requirements of electronics. For example, rather than producing parts by the millions, these companies need to be able to source their parts and materials in lower volumes–something their internal operations are often not set up to support. And for companies in regulated industries, they need to produce domestically to keep up with governmental requirements.

Cofactr automates and manages processes at the intersection of getting products to market fast and navigating rigorous corporate and governmental processes.

What market does Cofactr target and how big is it?

We work with a mix of hardware manufacturers and R&D groups at major digital enterprises with ambitious plans to diversify into hardware products. Our customers span both high-compliance sectors, such as aerospace, defense, robotics and medical technology, and consumer-facing industries, such as autonomous vehicles and wearables.

One of our first clients in a high compliance industry was Stoke Space. Working with them gave us insight into the challenges aerospace companies face with data sovereignty, materials traceability and quality management requirements – all issues companies in other heavily regulated industries face as well. We saw the opportunity in the sector to make a difference by solving the specific problems they were facing and it shifted our focus to the space.

When we look at the specific sectors we work, there’s so much opportunity to grow our work with customers. The U.S. aerospace and defense market alone is one of the largest in the U.S. for manufacturing and infrastructure, currently estimated at $497 billion in 2024 and expected to grow to $657 billion by 2029.

What’s your business model?

We offer a modular SaaS platform that allows startups and smaller teams to start affordably and adopt additional, more advanced capabilities as they grow. Our customers also have the option to procure parts through our managed network of suppliers and utilize our managed inventory services, both of which are charged based on usage. This approach ensures customers only pay for what they need while having the ability to expand as their operations evolve.

How are you preparing for a potential economic slowdown?

We’ve seen a strong adoption from teams tasked with doing more with fewer resources, which positions Cofactr to be well-positioned to navigate economic slowdowns. On top of that, solving the day-to-day challenges of managing complex supply chains becomes even more critical in times of economic and geopolitical disruption, making Cofactr an important tool to address these challenges effectively.

What was the funding process like?

We are fortunate to have had a strong multi-year partnership with Bain Capital Ventures and many of our other investors. BCV preempted this round, building on their three years of experience working with the Cofactr team, and were joined by our other existing investors – Y Combinator, Broom, Floating Point, and DNX – which were also enthusiastic about participating.

What are the biggest challenges that you faced while raising capital?

Raising capital for a multifaceted business and product like ours comes with the challenge of clearly communicating the full spectrum of value we deliver, how that connects to our financials and how we see that evolving over time. Fortunately, this was a largely inside round, so we had the benefit of working with investors who were already familiar with our journey and the progress we’ve made.

What factors about your business led your investors to write the check?

We immediately clicked with Ajay Agarwal and the Bain Capital Ventures team when we met them ahead of our seed funding in 2022. The BCV team immediately understood the problems we were solving and saw the opportunity of bringing together the many disparate pieces of hardware, logistics and software. They also had significant expertise in the space having backed companies in the logistics and supply chain space.

BCV making a third investment within three years reinforces their belief in our mission and their confidence in our ability to solve these supply chain and logistics problems that innovative hardware manufacturers face. The investment of existing Seed investors Y Combinator, Floating Point Ventures, Broom and DNX also mirrors that sentiment.

What are the milestones you plan to achieve in the next six months?

We’re in full-steam-ahead mode on shipping several major new platform capabilities over the next six months. Some of these include an improved AI-powered source-to-quote module, as well as more advanced approval and collaboration tools to support the larger enterprise teams that rely on Cofactr.

What advice can you offer companies in New York that do not have a fresh injection of capital in the bank?

My advice to any startup, whether or not they have fresh capital, is to focus on finding a user base with challenges that are both exciting and motivating. It’s important to remain deeply curious about those challenges and to tackle the hardest, most intimidating aspects of the problem, as these are often the greatest opportunities for growth.

Where do you see the company going now over the near term?

Right now, we’re focused on building on our momentum by scaling our go-to-market efforts and expanding the capabilities of our platform. Over the next few quarters, we’ll also introduce additional product categories and launch multiple new application modules.

To support this growth, we’re prioritizing hiring across our engineering and customer support teams to keep up with our growing customer base. This will allow us to maintain the high level of service and innovation our customers expect from us.

What’s your favorite winter destination in and around the city?

As an avid skier, my go-to winter destination is Hunter Mountain. It’s only about 2.5 hours away from the city, which makes for a great day trip.