The recent breaking news story on The Robot Report was, unfortunately, the demise of Helen Greiner’s company, CyPhy Works (d/b/a Aria Insights). The high-flying startup raised close to $40 million since its creation in 2008, making it the second business founded by an iRobot alum that has shuttered within five months. While it is not immediately clear why the tethered-drone company went bust, it does raise important questions about the long-term market opportunities for leashed robots.

The tether concept is not exclusive to Greiner’s company, there are a handful of drone companies that vie for market share including FotoKite, Elistair, and HoverFly. The primary driver towards chaining an Unmanned Aerial Vehicle (UAV) is bypassing the Federal Aviation Administration’s (FAA) ban on beyond line of sight operations. Therefore the only legal way to truly fly autonomously, without a FAA waiver, is attaching a cord to the machine. There are a host of other advantages such as continuous power and data links. In the words of Elistair customer Alexandre Auger of Adéole, “We flew 2 hours 45 minutes before the concert and 1 hour after with Elistair’s system. This innovation allowed us to significantly increase our flight time! During our previous missions, we did not have this system and the pressure related to battery life was huge.”

Most of the millions of robots installed around the world are stationary and, thus, tethered. The question of binding an unmanned system to a power supply and data uplink is really only relevant for units that require mobility. In a paper written in 2014 Dr. Jamshed Iqbal stated, “Over the last few years, mobile robot systems have demonstrated the ability to operate in constrained and hazardous environments and perform many difficult tasks. Many of these tasks demand tethered robot systems. Tether provides the locomotion and navigation so that robot can move on steep slopes.” Most robotic companies employed leashes five years ago, even mobility leader Boston Dynamics. However, today Marc Raibert’s company has literally cut the cord on its fleet, proving once and for all that greater locomotion and agility await on the other side of the tether.

Recently, Boston Dynamics unveiled its latest breakthrough for commercializing unhitched robots – freewheeling warehouse-bots. In a video on YouTube! that has already garnered close to a million views, a bipedal wheeled robot named Handle is shown seamlessly palletizing boxes and unloading cartons onto a working conveyor belt. Since SoftBank’s acquisition of Boston Dynamics in 2017, the mechatronic innovator has pivoted from contractor of defense concepts to a purveyor of real-world robo-business solutions. Earlier this year, Raibert exclaimed that his latest creations are “motivated by thinking about what could go in an office — in a space more accessible for business applications — and then, the home eventually.” The online clip of Handle as the latest “mobile manipulation robot designed for logistics” is part of a wider marketing campaign leading up to ProMat 2019*, the largest trade show for supply chain automation held in Chicago later this month.

According to the company’s updated website, Handle, the six foot two-hundred pound mechanical beast, is “A robot that combines the rough-terrain capability of legs with the efficiency of wheels. It uses many of the same principles for dynamics, balance, and mobile manipulation found in the quadruped and biped robots we build, but with only 10 actuated joints, it is significantly less complex. Wheels are fast and efficient on flat surfaces while legs can go almost anywhere: by combining wheels and legs, Handle has the best of both worlds.” The video is already creating lots of buzz on social media with Evan Ackerman of IEEE Spectrum tweeting, “Nice to see progress, although I’ve still got questions about cost-effectiveness, reliability, and safety.”

To many in the retail market palletizing is the holy grail for automating logistics. In a study released earlier this month by Future Market Insights (FMI) the market for such technologies could climb to over $1.5 billion by 2022 worldwide. FMI estimated that the driving force behind this huge spike is that “Most of the production units are opting for palletizing robots in order to achieve higher production rates. The factors that are driving the palletizing robots market include improved functionality of such robots along with a simplified user interface.” It further provided a vision of the types of innovations that would be most successful in this arena, “Due to the changing requirements of the packaging industry, hybrid palletizing robots have been developed that possess the flexibility and advantages of a robotic palletizer and can handle complex work tasks with the simplicity of a conventional high speed palletizer. Such kind of palletizing robots can even handle delicate products and perform heavy-duty functions as well, apart from being simple to use and cost effective in operations.” Almost prophetic in its description, FMI described Handle’s free-wheeling demonstration weeks before the public release by Boston Dynamics.

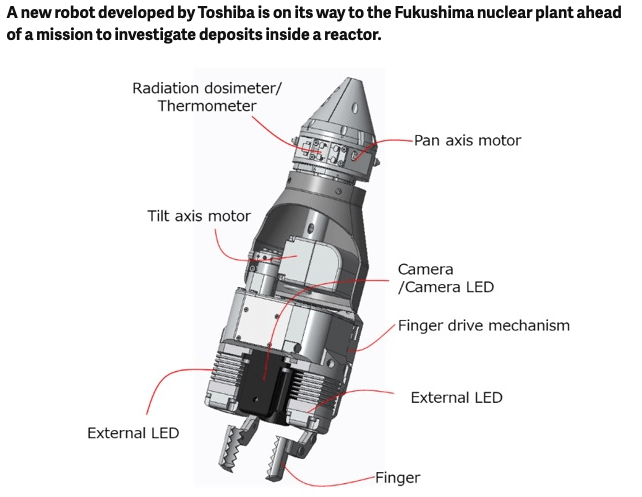

The mantra for successful robot applications is “dull, dirty and dangerous.” While advances like Handle continue to push the limits of mobility for the “dull” tedious tasks of inventory management, “dirty and dangerous” use cases require more continuous power than ninety minutes. By example, tethered machines have been deployed in the cleanup efforts of the Fukushima Daiichi Nuclear Power Plant since the tsunami in March 2011. The latest invention released is a Toshiba robot packed with cameras and sensors that include “fingers” for directly interacting the deposits of the environment enabling deeper study of radioactive residue. In explaining the latest invention, Jun Suzuki of Toshiba said, “Until now we have only seen those deposits, and we need to know whether they will break off and can be picked up and taken out. Touching the deposits is important so we can make plans to sample the deposits, which is a next key step.”

The work of Suzuki and his team in creating leashed robots in disaster recovery has already spilled over to new strides for underwater and space exploration. The Japanese Aerospace Exploration Agency announced a partnership with GITAI to build devices for the International Space Station. In the words of GITAI’s CEO, Sho Nakanose, “GITAI aims to replace astronauts with robots that can work for a long time while being remotely controlled from Earth while in low Earth orbit space stations to reduce the burden on astronauts, shorten the time it takes to perform work in space, and reduce costs.”