Every business has workflows or pipelines it must maintain to keep operations running. Manufacturing companies consume raw materials to create finished products. In turn, the sales department sends the products out the door to its customers. Internet tech startups aren’t any different. From hiring, lead generation, data on boarding and sales pipelines all the way down to the software release management, every company produces some sort of good or service that can break down into a series of workflows.

People play an incredibly large part in every company’s workflow. However, us humans can be costly and hard to manage, which creates a challenge when scaling horizontally. A human can only remember so much. Without machines it becomes impossible to grow effectively. With the advent of commodity software in our workflows, we can scale by multiples and make the humans we have on staff more efficient.

Software is definitely the answer to hit multiples of scale. But on the flip side, outsourced human labor has also become a commodity due to services like Amazon’s mTurk to labor on oDesk and eLance. We’ve even successfully hired dozens of folks locally for over a year from Craigslist when we really need to maintain a high degree of data integrity and skill. One could easily achieve another level of scale by just hiring more people.

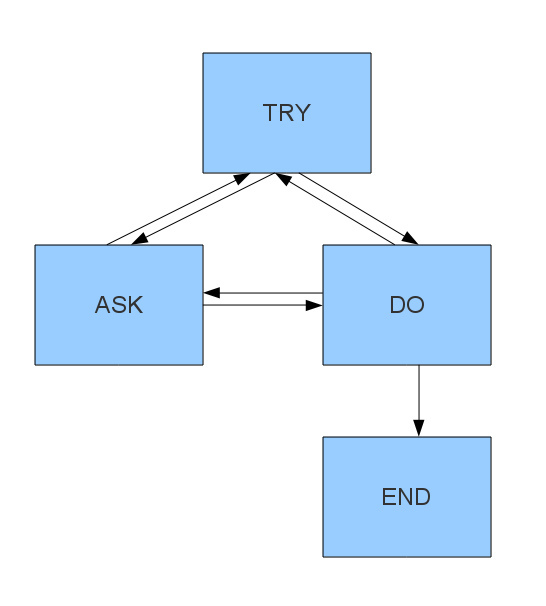

The big question really is, “Where is the line between human intervention and software automation?” If you’re automating something of a known quantity, software is clearly your answer. But if you’re a fast-paced startup and need to pivot quickly, you wouldn’t architect an entire software stack around an ever-changing business model.

This is exactly how UPS scaled their business. They used humans extensively and slowly automated different pieces of their jobs. They wrote one script after another, until finally they strung them all together into a pipeline of software. They did this for the same reason we do it: they were in uncharted waters. There’s no reason to double down on engineering that is ten times more expensive than much cheaper labor that can adapt quicker than machines.

Discovering Inefficiencies

Unfortunately every business is different and identifying scaling problems takes proper vision and knowledge. To me, there’s one rule that you should constantly build upon: That which is measured is improved. You cannot even begin to optimize until you find the highest level of return or biggest problem area to focus on. Sure you can blindly go into different departments to help them optimize — but how do you decide where to start?

The analogy I like to think of is diagnosing car troubles. If your water temperature gauge doesn’t work but your voltage gauge does and you solve your electrical issues, your car still may overheat down the road. In reality, you can fix the battery issues later as long as the car starts. But the highest value of return would come from fixing the overheating issues immediately.

Solving Inefficiencies

Taking a scientific approach to solving these problems is the most financially prudent and effective way to find scaling solutions. There are a few ways we have gone about doing this. The easiest (also least likely) way is to have the humans tell the engineers what they spend their day doing. This helps the engineers keep their heads down on other projects without directly getting involved in the nitty-gritty.

Unfortunately, not many non-engineers are able to actually explain what it is they do all day in enough detail to replicate. We’ve had mixed success. Our staff is learning how to distill their use cases down more and more. In order to help them discover inefficiencies, we have one golden rule: if you find yourself doing the same task for more than a few hours a day, tell your boss or the engineers immediately.

Question your job. Don’t just do something because you are told to do so. Many folks have a hard time with this concept and just want to please their boss. But the only way to get to the next level of scale is by being introspective.

The other way we find inefficiencies is by having engineers shadow employees with highly repeatable workflows. In some cases, we have even removed the human from the task for a few weeks while the engineer fills in to really dig deep into the problem. This can be a painful process for the engineer but it achieves extremely good results.

Knowing When to Stop

Always remember that just because you can do something doesn’t mean you should. Much like writing web software, scaling pipelines is an iterative process and it’s much easier to roll forward than to roll backward. Removing all the human touch points too fast will mask problems and likely create more. Automation itself needs to be monitored, or else you will lose sight of what’s really happening.

One of the tricks we employ is going to the point of complete automation — minus the final step. We do this for quality control purposes in many cases. For example, let’s say you need to gate an approval process part of your system. Rather than automatically approving an event to happen, we send an email to the administrators with the proper information they need to make the decision and several URL links. This is our way of gating sensitive or otherwise high-risk events that require human attention. It buys us many levels of scale without sacrificing quality. If we hit the next level of scale and still require humans for quality, we can easily outsource this for very little cost.

Some pipelines will always require human interaction. As we scale up it becomes more and more important to have a complete picture as to the status of your pipelines.

There really is no silver bullet to any of these problems. Solutions come from careful study and measurement. Software alone cannot solve all of your logistics problems, just as humans will never be able to achieve the same scale without software. Since humans are smarter than machines and will be for the foreseeable future, you need to weld the two together. Finding out how far to push the automation is really based on your business needs and how closely you study your logistical systems.

My recommendation for anyone attempting to scale up their logistical pipelines — from shipping product to onboarding data — is to use humans and study their behavior closely. It will cost you less and deliver a better more accurate end result. Measure twice and cut once.

The Young Entrepreneur Council (YEC) is an invite-only organization comprised of the world’s most promising young entrepreneurs. In partnership with Citi, YEC recently launched StartupCollective, a free virtual mentorship program that helps millions of entrepreneurs start and grow businesses.

Image credit: CC by doryfour